Introduction

3D printing, also known as additive manufacturing, has emerged as one of the most groundbreaking technologies of the 21st century. It enables the creation of three-dimensional objects layer by layer, offering unparalleled design flexibility and manufacturing capabilities. Since its inception, 3D printing has made significant strides in various industries, from healthcare and aerospace to fashion and automotive. In this article, we explore the evolution of 3D printing, its current applications, and the exciting possibilities it holds for the future.

The Genesis of 3D Printing

1.1. Early Beginnings

The concept of 3D printing dates back to the 1980s when Charles Hull invented stereolithography, a technique that used UV light to solidify a liquid photopolymer resin layer by layer. This marked the birth of the additive manufacturing process that underpins 3D printing.

1.2. Advancements in Technology

Over the decades, technological advancements and the expiration of key patents have led to the democratization of 3D printing. The availability of affordable desktop 3D printers and open-source software has spurred widespread adoption among hobbyists, researchers, and small businesses.

3D Printing Processes and Materials

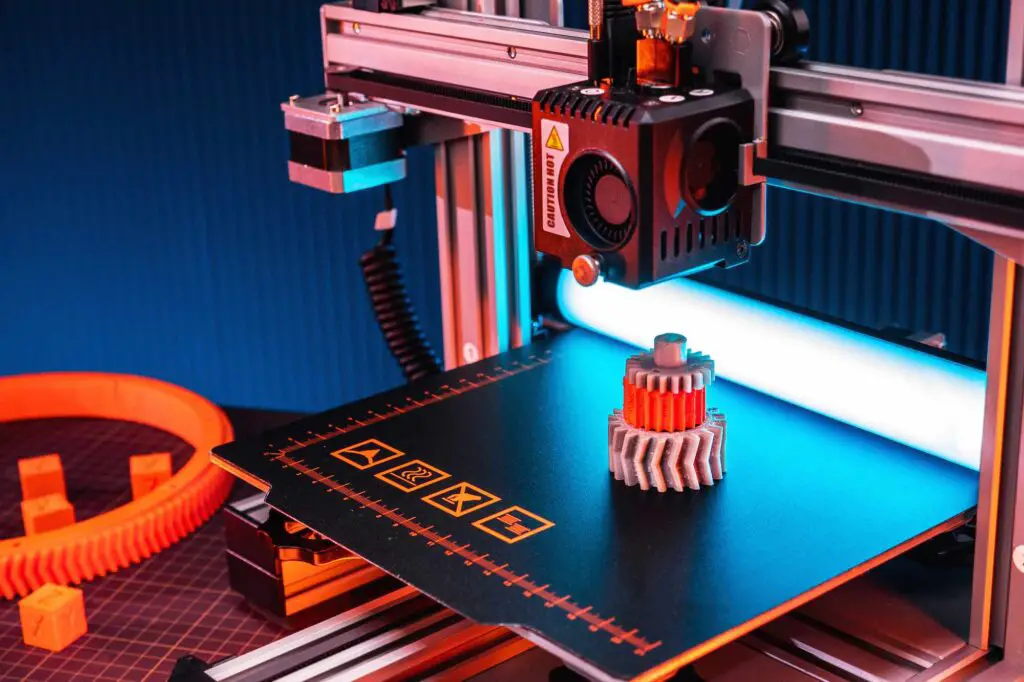

2.1. Fused Deposition Modeling (FDM)

FDM is one of the most common 3D printing processes, in which a thermoplastic filament is heated and extruded through a nozzle, layer by layer, to create the final object.

2.2. Stereolithography (SLA)

SLA involves using a laser to selectively cure a liquid resin into a solid, layer by layer. It is widely used for high-resolution and intricate prints.

2.3. Selective Laser Sintering (SLS)

SLS uses a high-powered laser to sinter powdered materials, such as plastics, metals, and ceramics, layer by layer, to create durable and complex objects.

2.4. Digital Light Processing (DLP)

DLP utilizes a digital light projector to selectively cure a liquid photopolymer resin into a solid, resulting in faster print times compared to SLA.

2.5. Metal 3D Printing

Metal 3D printing, or additive metal manufacturing, employs techniques like Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) to produce metal parts for aerospace, automotive, and medical applications.

Current Applications of 3D Printing

3.1. Rapid Prototyping and Product Development

3D printing allows rapid prototyping, reducing lead times and costs in product development. Engineers and designers can quickly iterate and refine designs before mass production.

3.2. Healthcare and Medical Applications

The medical industry has embraced 3D printing for surgical planning, custom prosthetics, patient-specific implants, and the creation of anatomical models for education and practice.

3.3. Aerospace and Automotive

In aerospace and automotive sectors, 3D printing offers lightweight and complex components that enhance fuel efficiency and performance. It also streamlines the supply chain by producing spare parts on demand.

3.4. Architecture and Construction

3D printing in architecture and construction enables the creation of innovative and sustainable structures. Large-scale 3D printers can fabricate building components and even entire houses.

3.5. Fashion and Design

3D printing has brought new possibilities to the world of fashion and design, enabling the creation of customizable and intricate clothing, accessories, and footwear.

Advantages and Limitations of 3D Printing

4.1. Advantages

Design Freedom: 3D printing allows complex and customized designs that are challenging to achieve with traditional manufacturing techniques.

Cost-Efficiency: For low-volume production and rapid prototyping, 3D printing can be more cost-effective than traditional methods.

Sustainability: Additive manufacturing generates less waste compared to subtractive manufacturing processes.

On-Demand Manufacturing: 3D printing enables just-in-time production, reducing inventory and storage costs.

4.2. Limitations

Speed: 3D printing can be slower compared to traditional mass production methods, especially for large and intricate objects.

Material Limitations: While 3D printing materials continue to expand, certain materials, especially high-performance metals, can be challenging and expensive to work with.

Quality Control: Achieving consistent quality and structural integrity can be a challenge, especially with complex designs and large-scale prints.

Future Trends and Innovations

5.1. Bioprinting and Organ Transplants

The field of bioprinting holds great promise for producing living tissues and organs for transplant, potentially revolutionizing the medical industry.

5.2. Industry 4.0 and Smart Factories

Integration of 3D printing with artificial intelligence and automation will lead to smart factories capable of on-demand production and personalized manufacturing.

5.3. Space Exploration and Colonization

3D printing is poised to play a crucial role in space exploration, where on-site manufacturing of tools and equipment can reduce the costs and challenges of interplanetary missions.

5.4. Food and Sustainability

Innovations in 3D food printing may contribute to addressing global food shortages and reducing food waste by producing personalized and nutrient-dense meals.

Societal and Ethical Implications

6.1. Intellectual Property and Copyright Issues

The ease of replicating objects with 3D printing raises concerns about intellectual property rights and copyright infringement.

6.2. Job Disruption and Skilled Labor

The widespread adoption of 3D printing may lead to job displacement in certain industries, necessitating a focus on upskilling and retraining the workforce.

6.3. Environmental Impact

While 3D printing can reduce waste in some cases, the materials used and energy consumption may pose environmental challenges that require careful consideration.

Conclusion

3D printing has come a long way since its inception, reshaping industries and revolutionizing manufacturing processes. Its potential to drive innovation, sustainability, and personalized products is vast. As technology continues to evolve, 3D printing holds the key to solving complex challenges across various sectors. However, addressing its limitations and ethical implications is essential to harness its power responsibly. As we enter a new era of manufacturing and creativity, embracing the revolutionary potential of 3D printing will undoubtedly shape a more dynamic and innovative future for humanity.